PowerMaster Model CSWI is designed for use on gates with a maximum weight of 1800 pounds and a maximum width of 30 feet. The gate will travel from open to close in approximately 13 seconds, and it is rated for a maximum of 45 cycles per hour. The CSWI is available for 1/2hp to 1- 1/2hp in single or three phase. The drive arm is easily disconnected for manual operation. The CSWC is UL 325 listed for use in Class I through Class IV applications. Shipping weight is approximately 300 pounds.

Product Highlights:

- Part Number: POWERMASTER-MODEL-CSWI-SWING-GATE-OPERATOR

- Controls Industrial Vehicular Swinging Gates

- Easy Set Limits

- Timer to Close

- Master/Slave Operation

- Left/Right Changeover in Field

- Built-In Control Station for Easy Setup

- NEMA-1 three-button control station

Technical Information:

- Power Requirements: 115/230 Volts, 1 phase OR 230/460 Volts, 3 phase

- Control Circuit: Class 2 low voltage

- Available Horsepower: 3/4 HP - 2 HP

- Maximum Gate Weight: 1800 lbs.

- Maximum Cycles Per Hour: 45 CPH

- Maximum Gate Width: 30 feet

- Gate Speed: 18 seconds from open to close

- UL 325 Listed: for use in Class I through IV applications

- Shipping Weight: approximately 300 lbs.

Optional Equipment:

- Radio Control

- Safety Edge (contact safety sensor)

- Photo Cell (non-contact safety sensor)

- Loop Detector

- Card Key Reader

- Gear Box Heater (for cold climates)

- Thermostatically Controlled Cooling Fan (for hot climates)

- Interior and Exterior Control Stations:

- Push Buttons

- Push Button with Keyed Lockout

- Key Switches

- Padlockable Option (to secure cover for increased tamper proof protection)

- Three Second Advance Audio Warning Signal (available upon request)

Electrical Specifications:

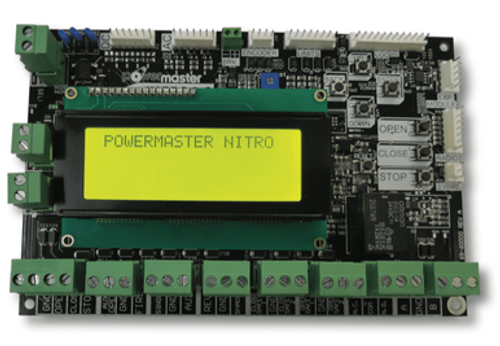

- Solid state control board with diagnostic LED's to indicate all input and output functions

- External control input termal connections for:

- Radio Receiver

- Push Button Control Station

- Key Switches

- Loop Detectors

- Card Key Readers

- Telephone Entry Systems, etc.

- Timer to close with 0-60 sec. adjustment standard (longer timer available upon request)

- Self-adjusting maximum run timer for equipment protection

- Master/Slave option provided with dedicated terminal connection

- Easy Left/Right changeover

- Time delay on reverse

- Surge and lightening protection with spike suppressing circuitry

- Precise gate positioning with electrical dynamic brake

- Integral, current sensing, anti-entrapment circuitry with independent opening and closing sensitivity adjustments

- External anti-entrapment circuitry with separate terminal connections for easy installation of contact and non-contact sensors

- Internal On/Off power switch

Mechanical Information:

- Heavy duty #7 Ga. steel frame

- Protection from the elements with hard shell baked-on weather resistant powder coated and textured finish

- Smooth, quiet and positive operation with timing belt primary reduction

- Heavy duty 45:1, oil bath type gear reducer for long service and dependable operation

- Heavy duty #50 sprocket and roller chain arrangement for final drive reduction

- Heavy duty pillow block type ball bearings supporting output drive shaft and enabling extended endurance under heavy loads with low maintenance

- Drive arm easily disconnected for manual operation in the event of a power failure

- Easily adjustable limit switch cams for precision gate positioning

- Soft start and stop at the open and close limits of travel due to the inherent geometry of the articulating drive arm linkage

- Pad mounted