Introducing LiftMaster’s New MAXUM Series Commercial Operators

Posted by Charlene Pepiot on 5th Jan 2024

Introducing LiftMaster’s New MAXUM Series of Commercial Operators

It’s time to raise your commercial operations to greater heights with LiftMaster’s new MAXUM door operators for commercial applications! This new generation puts versatility and function first with sleek, purpose-built designs that are easier to install and service than prior models. Below you’ll find our expert analysis on the new features of the JDC Jackshaft, JHDC Hoist and TDC Trolley rolling out in early 2024.  |

TABLE OF CONTENTS

|

What are LiftMaster’s New MAXUM Lineup of Commercial Operators?

Always at the cutting edge of the garage door and access point industry, LiftMaster's next generation of commercial operators are designed with the installer and end user in mind. Aside from the new sleek design; they are lighter, easier to install and easier to service. Boasting unparalleled efficiency and sophistication, these new generation of operators is poised to take commercial facilities towards a more intelligent future.

LiftMaster purposely reduced the number of commercial operator SKUs to simplify logistics. This doesn't mean that the customization of each operator is gone as well. Now each operator requires the purchase of a specialized kit that allows it to be customized to each unique application where it is installed. For the jackshaft based JDC and JHDC operator they require a Sprocket Kit depending on the door that it is being installed on. There is a separate Sprocket Kit for Rolling Steel Doors and Sectional Doors.

For the Trolley Operator (TDC) there is a specialize Track and Chain Kit that needs to be purchased for proper installation. The kits depend on the size of the operator. For door weighting 700 pounds or less the TDC7 operator is used, which requires the TDC7-RAILS kits. For doors weighting 1200 pounds or less the TDC12 operator is applied and TDC12-RAILS. The same rails for TDC12 can also be used for door weighing over 2200 pounds using the TDC22 operator.

LiftMaster's three commercial operators offering:

1. JDC JackshaftThis next-generation standard duty Jackshaft (non-hoisted) MAXUM DC operator supports sectional or rolling doors of up to 700 lbs in NEMA 1 applications. Jackshaft operators like the JDC are preferred over trolleys in applications where the overhead space is at a premium. It is also battery backup capable. |

|

2. JHDC HoistUnlike the JDC Jackshaft, the JHDC is hoisted. It operates as a standard or extended-duty Jackshaft DC operator and supports sectional and rolling doors that weigh up to 2200 lbs in NEMA 1 or NEMA 4X applications. JHDC operators include a hand chain hoist for manual door movement and are battery backup capable. |

|

3. TDC TrolleyThe last operator rolling out in early 2024 from LiftMaster’s next generation is the standard or extended duty TDC operator. It supports standard-lift sectional doors up to 2200 lbs in NEMA 1 or NEMA 4X applications and is also battery backup capable. |

|

What Does LiftMaster’s MAXUM Commercial Door Operators Offer?

All operators within the innovative MAXUM generation boast a smooth start and stop operation that extends the life of the operator and door hardware. Their optional battery backup capabilities mean that operation can continue during a power outage—a crucial feature in commercial settings that adhere to strict schedules.

Each operator boasts a floor-level wall control 4-line LCD display that brings programming, troubleshooting, and diagnostics down to your level to save you time and money. Wave goodbye to confusing LED flashes and embrace real-time alerts and relevant information through the operators’ smart control panel for advanced diagnostics and troubleshooting. The Control Board is designed to have everything at your fingertips, with the new push-and-play and color-coded terminals designed with you in mind for easy identification of all your wiring needs.

LiftMaster’s new generation of operators has also lightened the load to make installation easier! The new 700 Jackshaft garage door opener and Hoist operator are 30 lbs. lighter than the 1/2 HP Logic 5.0 operator of the previous generation. MAXUM operators also have 3 monitored entrapment protection inputs and high-efficiency motors and gearboxes for your convenience.

In addition, LiftMaster commercial door operators are UL® Listed and listed to ANSI/CAN/UL325 standards for the USA and Canada and are certified to NOM/IFETEL standards for Mexico. MAXUM operators also have built-in Wi-Fi capabilities, and with LiftMaster’s myQ technology, you can see what is happening at your door and control it from your web browser.

For a more in-depth look at extra accessories and maximum door weight requirements, read our MAXUM Buyers Guide here.

What are MAXUM Operators' Key Features & Specifications?

JHDC Hoist Operator Key Features

If you own a sectional door (standard lift, high lift, and full vertical) or any rolling steel doors/grilles, the JHDC Hoist Operator is a solid operator choice. With a rated duty cycle standard of up to 20 cycles per hour and 90 cycles per day as well as extended duty capabilities of up to 30 cycles per hour and 150 cycles per day, it’s great for busy commercial environments. A manual hoist is required for both the standard duty and extended duty cycles. The operator’s speed averages 12" per second on sectional doors and 8-9" per second on rolling steel doors so you aren’t waiting around for to long for the door to finish its cycle.

For your convenience, you can use the floor level wall controller with its LCD display to program and commission the door. The operator uses a DC Logic Circuit Board. The emergency disconnect for manual operation comes in the form of the operator’s engage rope (green) and a disengage rope (red) with a manual hoist to disable the operator controls electrically. The emergency disconnect with auto-reconnect also includes an engage rope (green) and a disengage rope (red) with a manual hoist to disable the operator controls electrically. You can pull the engage (green) rope to operate the door again electrically. You can also program a timer to close the door through the menu on the wall controller. The option is available in B2 Mode with two settings.

The JHDC operator is built with an industrial-grade design. Its plastic E-Box is rigid and flexible and it has integrated hinge snap features and a durable metal chassis frame. Without a heater, the temperature is -4°F (-20°C) to 140°F (60°C). With a heater (HTR) the temperature ranges from -40°F (-40°C) to 140°F (60°C).

When purchased, the carton will include the operator, CPS-U (NEMA 4X units include CPS-UN4), DCWALLCTL, mounting hardware, antenna, and 25 ft. of hoist chain (additional chain can be purchased separately). Door sprockets are available but sold separately.

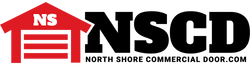

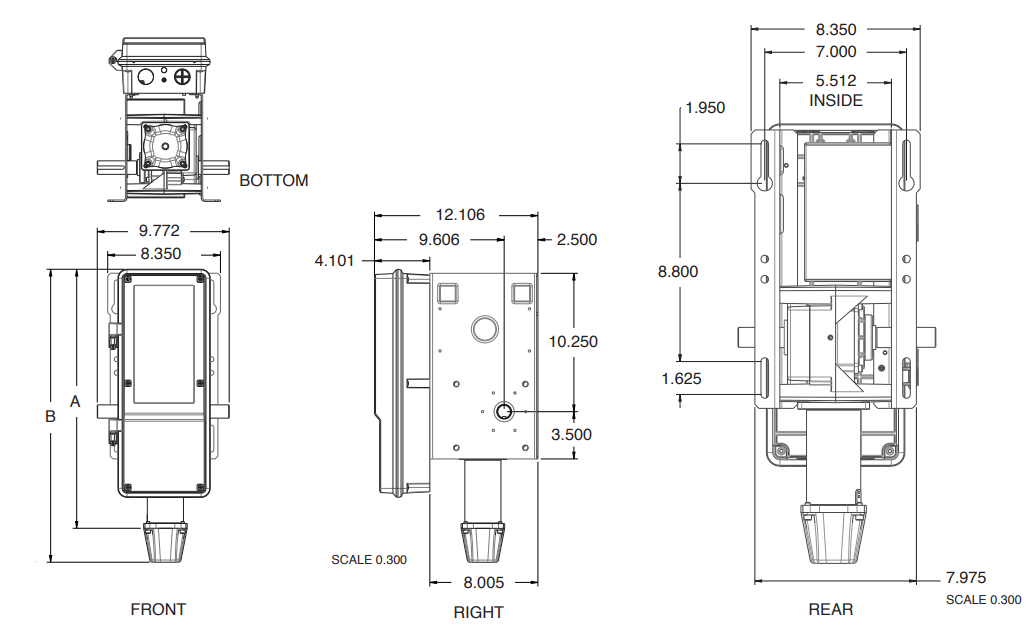

Dimensions:

- Operator for 700 pound doors / 9.772” W x 19.1” H x 12.1” D

- Operator for 1200 pound doors / 9.772” W x 19.5” H x 12.1” D

- Operator 2200 pound doors / will be released in 2025

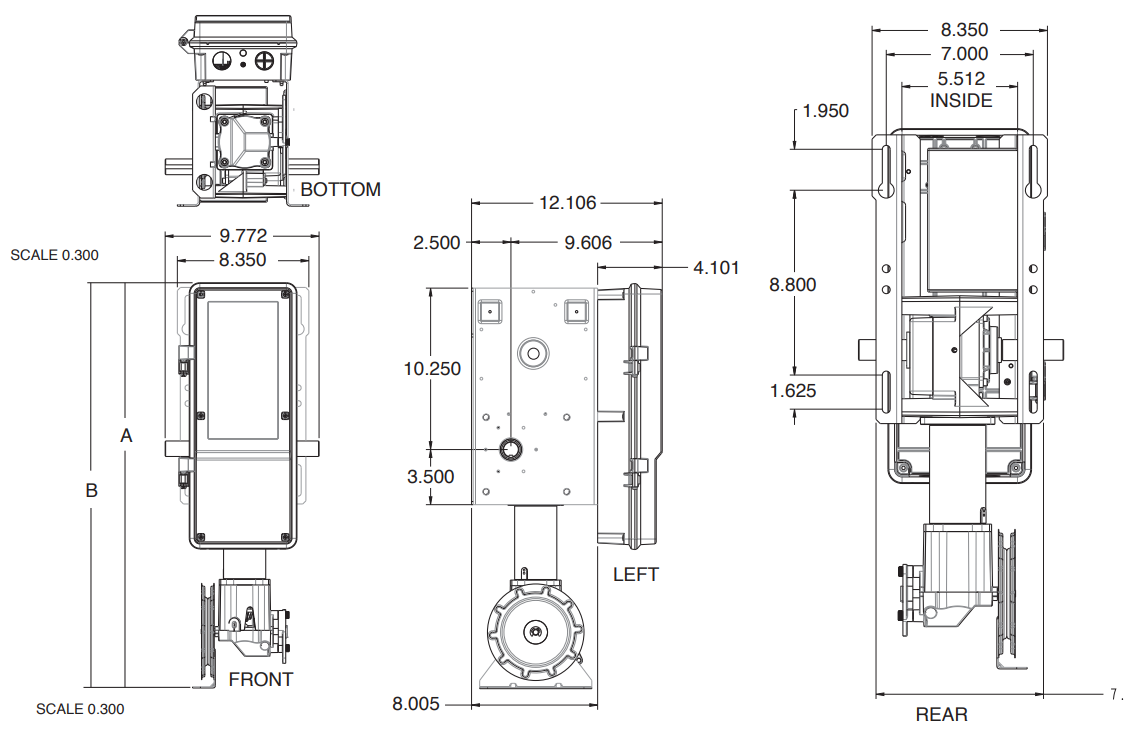

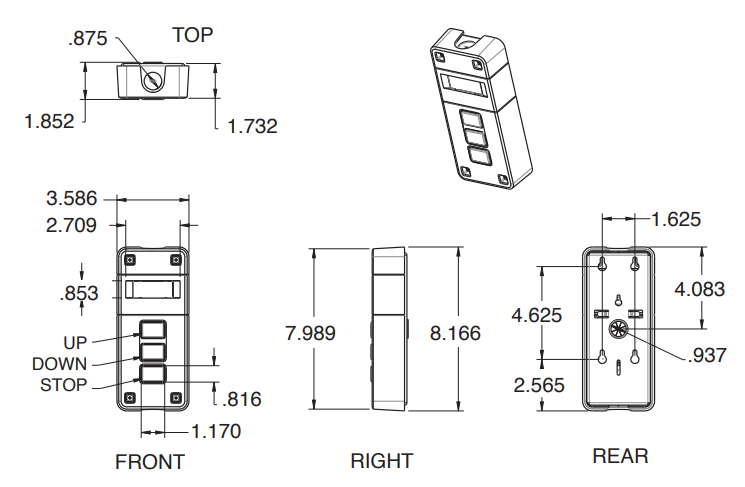

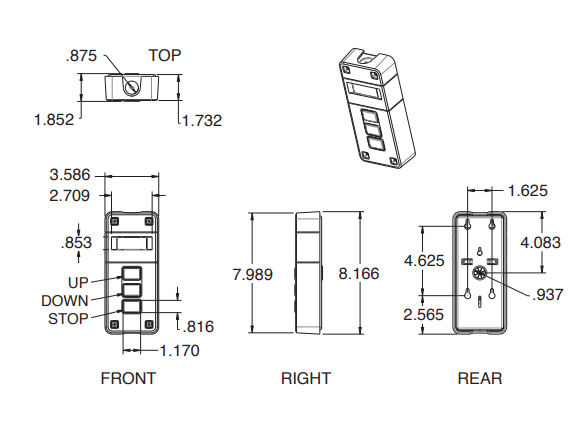

- Floor Level Wall Controller: 3.586” W x 8.166” H x 1.732” D

|

|

Specifications:

- 24VDC Motor Drive

- Electromechanical Brake for operators that support 700 lbs. and 1200 lbs. doors, 2200 lbs.

- Operators brake is standard

- Dual Handing: right or left no longer required for order

- Mounted Keyhole Slots: created for installers to easily access and fasten the operator to the wall

- Removable Front Cover

- Captive E-Box screws: remain in place when opening and removing cover

- Power: 120Vac 1 PH/240Vac 1/3PH; 480Vac 3PH; 208Vac 3PH (via transformer); 600Vac 3PH (via transformer)

- Accessory Power: 24Vdc, 1A Auxiliary Output

- Drive Reduction: 65:1 Gearbox with #50 Chain Output Brake

- Construction: NEMA 1 type electrical box, heavy-duty 11 gauge steel frame with durable powder coat finish. NEMA 4X type electrical box for NEMA 4X rated units

- Run Time Protection Standard: 20 Cycle Count and Cycle 21% within a 60-minute threshold Extended Duty: 30 Cycle Count and Cycle 37% within a 60-minute threshold

- Motor Reverse Action Protection Stop Fast: 250ms ramp Stop Ramp: 500ms-2000ms; Stop button while opening Emergency (Safety-Chain): CTM trigger immediate stop

- Battery Backup DC7AH (2): 7 Ah batteries and mounting bracket (optional)

- Warranty: 2 years

TDC Trolley Operator Key Features

The TDC Trolley Operator is ideal for standard lift sectional doors, standard duty cycle, and extended duty cycle applications. Its standard duty cycle is up to 20 cycles per hour and 90 cycles per day while the extended duty cycle is up to 30 cycles per hour and 150 cycles per day. With an operator speed average of 12" per second for sectional doors, you can minimize wait time during operation. If your door’s operation is on a schedule, you can program a Timer-to-Close through the menu on the wall controller as well as stop the door mid-way.

For your safety, the TDC Trolley Operator includes an emergency disconnect for manual operation and an auto-reconnect as well as motor reverse action protection. It also has the option for a mounting bracket and 7 Ah battery backup. The operator uses a DC Logic Circuit Board and requires a Dual L-Rail Trolley Track. Its E-Box has a rigid and flexible design along with integrated hinge snap features and a durable metal chassis frame. The temperature without a heater is -4°F (-20°C) to 140°F (60°C). With the heater (HTR), it is -40°F (-40°C) to 140°F (60°C).

For doors with a maximum weight of 700 pounds a TDC7 operator is the correct choice and for doors of 1200 pounds a TDC12 operator is what to use. For doors up to 2200 pounds require a TDC22 operator (release date 2025).

The carton contains the Operator, CPS-U (NEMA 4X units include CPS-UN4), DCWALLCTL, mounting hardware and antenna. You can purchase tracks, chains and spacers separately.

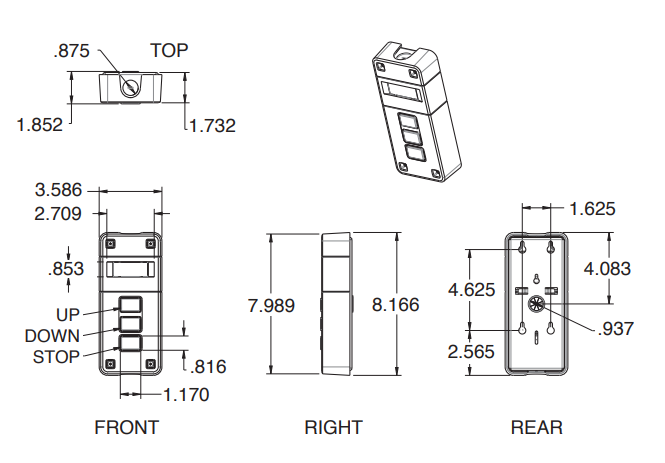

Dimensions:

- Operator for doors up to 700 pounds / 9.772” W x 19.1” H x 12.1” D

- Operator for doors up to 1200 pounds / 9.772” W x 19.5” H x 12.1” D

- Operator for doors up to 2200 pounds/ will be released in 2025

- Floor Level Wall Controller 3.586” W x 8.166” H x 1.732” D

|

|

Specifications:

- Power: 120Vac 1 PH/240Vac 1/3PH; 480Vac 3PH; 208Vac 3PH (via transformer); 600Vac 3PH (via transformer)

- Radio Receiver LiftMaster Security+ 2.0

- Voltage Connections: 120Vac 1 PH/240Vac 1/3PH; 480Vac 3PH; 208Vac 3PH (via transformer); 600Vac 3PH (via transformer)

- Accessory Power: 24Vdc, 1A Auxiliary Output Drive Reduction 65:1 Gearbox with #48 Chain Output on 700 units and #41 Chain Output on 1200 and 2200 units

- Brake Electromechanical for operators that support doors up to 700 and 1200 lbs. Brake is included on 2200 models.

- Construction NEMA 1 type electrical box, heavy duty 11 gauge steel frame with durable powder coat finish. NEMA 4X type electrical box for NEMA 4X rated units

- Warranty 2 years

JDC Jackshaft Operator Key Features

Those with rolling steel doors/grilles and sectional doors like standard lift, high lift, and full vertical should consider the JDC Jackshaft Operator. Its standard duty cycle can complete up to 20 cycles per hour and 90 cycles per day. The operator's average speed is 12" per second for sectional doors and 8-9" per second on rolling steel doors to minimize wait time during operation. The operator also features timer-to-close programming and mid-stop functions. For your safety, the operator has the option of a battery backup and motor reverse protection to stop the operator fast if needed. The JDC uses a DC Logic Circuit Board. It boasts an industrial-grade design, as its plastic E-Box has a rigid and flexible makeup along with integrated hinge snap features and a durable metal chassis frame. The temperature without heater is -4°F (-20°C) to 140°F (60°C). With the heater (HTR), it is -40°F (-40°C) to 140°F (60°C).

Dimensions:

- The operator has the following dimensions for doors up to 700 pounds / 9.772” W x 21.7” H x 12.1” D

- The Floor Level Wall Controller is: 3.586” W x 8.166” H x 1.732” D

|

|

Specifications:

- Power: 120Vac 1 PH/240Vac 1/3PH; 480Vac 3PH; 208Vac 3PH (via transformer); 600Vac 3PH (via transformer)

- 24VDC Motor Drive

- Radio Receiver LiftMaster Security+ 2.0

- Accessory Power: 24Vdc, 1A Auxiliary Output

- Drive Reduction 65:1 Gearbox with #50 Chain Output

- Brake Electromechanical for operators that support doors up to 700 lbs.

- Construction NEMA 1 type electrical box, heavy-duty 11 gauge steel frame with durable powder coat finish

- Mounted Keyhole Slots: easily access and hang the operator

- Removable Front Cover

- Captive E-Box screws: remain in place when opening and removing cover

- Warranty 2 years

Each purchase includes the following: the operator, CPS-U P DCWALLCTL, Battery Tray and (2) 4.5 Ah batteries, Mounting Hardware, and an Antenna. Door sprockets are available but sold separately.

Kits To Complete Your Operator Installation

Each of the new operators requires either a sprocket kit (JDC & JHDC) or a track and chain kit (TDC) to complete your installation.

The JDC and JHDC jackshaft operators require a sprocket kit to complete proper installation. These sprocket kits are attached to the side of the operator and depending on the door's weight will depend on the amount of teeth required to maintain the correct speed of a door going up or down.

JDC Sprocket Kits for Sectional Doors to maintain a speed of 12" per second.

| Door Lift Type: |

Drum: | Sprocket Tooth Count: |

| Standard | D400-96 | 16 |

| High Lift | D400-54 | 16 |

| Standard | D400-144 | 16 |

JDC Sprocket Kits for Rolling Steel Doors to maintain a speed of 8" to 9" per second.

Uninsulated Rolling Steel Doors

| Door Weight: |

Sprocket Tooth Count: |

| Up to 450 pounds | 50 |

| 450-700 pounds | 72 |

Insulated Rolling Steel Doors

| Door Weight: | Sprocket Tooth Count: |

| up to 450 pounds | 60 |

JHDC Sprocket Kits for Sectional Doors to maintain a speed of 12" per second.

| Door Weight: | Door Lift Type: | Drum: | Sprocket Tooth Count: |

| 700 pounds | Standard | D400-96 | 16 |

| 700 pounds | High | D400-54 | 16 |

| 700 pounds | Standard | D400-144 | 16 |

| 1200 pounds | Vertical | D850-132 | 22 |

| 1200 pounds | Standard | D5250-18 | 22 |

| 1200 pounds | High | D525-54 | 22 |

| 1200 pounds | High | D575-120 | 22 |

| 1200 pounds | Standard | D525-216 | 22 |

| 2200 pounds | Vertical | D1100-216 | 32 |

| 2200 pounds | High | D6375-164 | 32 |

| 2200 pounds | Standard | D800-384 | 32 |

| 2200 pounds | High | D800-120 | 32 |

| 2200 pounds | Vertical | D1350-336 | 42 |

JHDC Sprocket Kits for Rolling Steel Doors to maintain a speed of 8" to 9" per second.

Uninsulated Rolling Steel Doors

| Door Weight: | Sprocket Tooth Count: |

| up to 450 pounds | 50 |

| 450-700 pounds | 72 |

| 700-1200 pounds | 72 |

| 1200-1800 pounds | 72 |

| 1800-2200 pounds | 82 |

Insulated Rolling Steel Doors

| Door Weight: | Sprocket Tooth Count: |

| up to 450 pounds | 60 |

| 450-700 pounds | 72 |

| 700-1200 pounds | 72 |

| 900-2200 pounds | 82 |

The Trolley Commercial Operator (TDC) requires a track and chain kit to complete the installtion of this operator. To determine the correct track and chain kit you need, simply measure the door's height from bottom to top. 1 Kit contains 2 tracks, 1 chain and any needed spacers that are required for installation. Using the chart below as reference, you can purchase a TDC7 Rail Kit Here and TDC12 & TDC22 Rail Kit Here.

| Operator Size: | Door Height: | TDC Components Kit: |

| TDC7 Operator | 8 | TDC7-8 |

| TDC7 Operator | 10 | TDC7-10 |

| TDC7 Operator | 12 | TDC7-12 |

| TDC7 Operator | 14 | TDC7-14 |

| TDC7 Operator | 16 | TDC7-16 |

| TDC7 Operator | 18 | TDC7-18 |

| TDC7 Operator | 20 | TDC7-20 |

| TDC7 Operator | 22 | TDC7-22 |

| TDC7 Operator | 24 | TDC7-24 |

| TDC12 & TDC22 Operators | 8 | TDC1222-8 |

| TDC12 & TDC22 Operators | 10 | TDC1222-10 |

| TDC12 & TDC22 Operators | 12 | TDC1222-12 |

| TDC12 & TDC22 Operators | 14 | TDC1222-14 |

| TDC12 & TDC22 Operators | 16 | TDC1222-16 |

| TDC12 & TDC22 Operators | 18 | TDC1222-18 |

| TDC12 & TDC22 Operators | 20 | TDC1222-20 |

| TDC12 & TDC22 Operators | 22 | TDC1222-22 |

| TDC12 & TDC22 Operators | 24 | TDC1222-24 |

Go Further with MAXUM Operators!

North Shore Commercial Door has been a LiftMaster partner for decades, and you can preorder LiftMasters new products from us here! Once you’ve secured your new MAXUM operator, take your garage to greater heights by checking out LiftMasters array of optional accessories, listed on our handy blog! Also, stay on top of any potential garage issues by reading our Guide to Garage Door Maintenance.

Still Curious About LiftMaster Operators?

Please ask! Our in-house experts can help you with your questions for LiftMaster and other top brands on the market. Get in touch with our support crew:

- Live chat: Click the green "Contact Us" button on the right

- Call: 800-783-6112

- Email: support@northshorecommercialdoor.com